Overview of the LN100XT Version

Our concept keeps the snow inside the drag.

The pivot system allows the compactor to stay in a horizontal position no matter the height of the rear blades. The compactor plate is rounded at the rear allowing to back-up without having to raise the trail drag.

The sides are equipped with guides allowing for minimum friction to cause the least damage possible when in contact with trees. Moreover, the front of the drag is narrower then the tractor, it gradually widens to the rear to reach its nominal width. (taper frame).

The rear levelling cutters are 2 inches (50 mm) higher than the rest of the cutters. They distribute snow evenly to the compactor plate so that no areas are left without snow offering a uniform compact surface.

With the lever to the left position↑

With the lever to the right position↓

The front lever system is equipped with an anti-scalp device (available on the LN and LC series) allowing it to float or not on a hardned trail.

All cutters are equipped with an adjustable compression spring safety device.

Position of the compactor plate in transport mode.

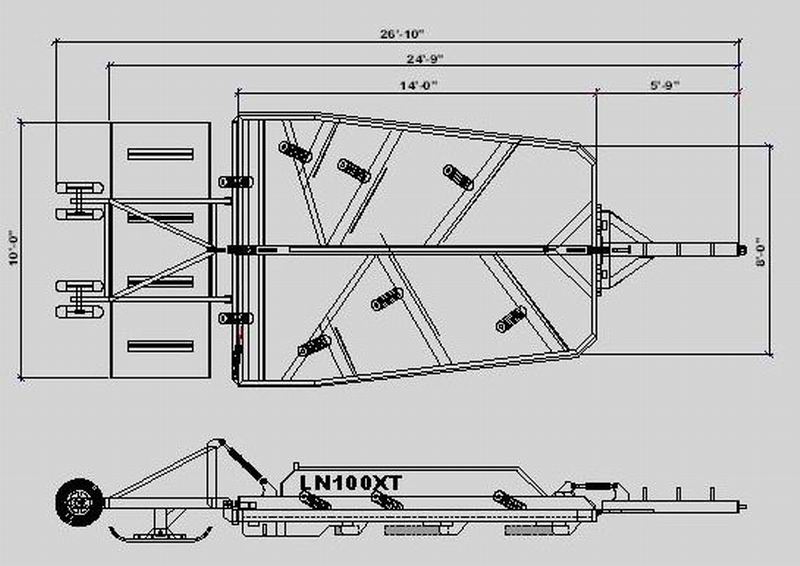

This drawing represents a 10 feet compactor width, the lateral lever system (XT)

and the standard hook attachment.

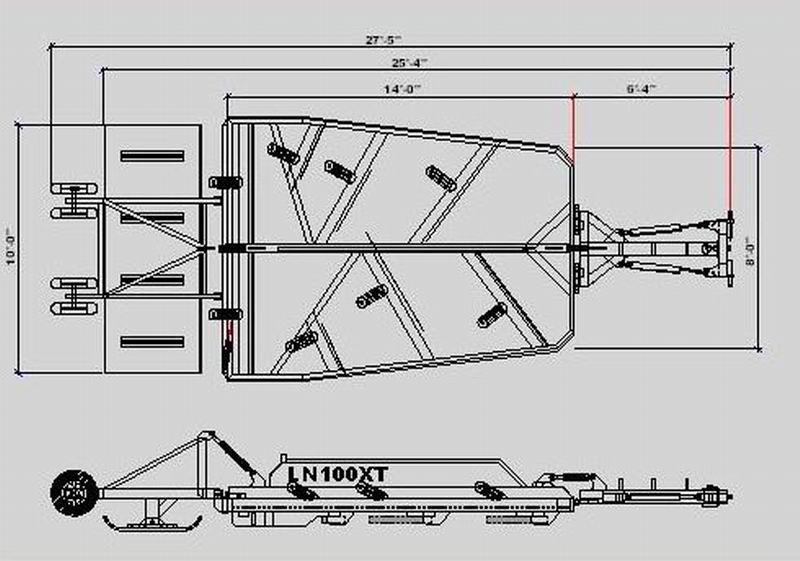

This drawing represents a 10 feet compactor width, the lateral lever system (XT)

and the hydraulic ram steer.